Preparing and Sharpening Stihl Chainsaw Chains

Preparing and Sharpening Stihl Chainsaw Chains

Preparing Chainsaw Chain

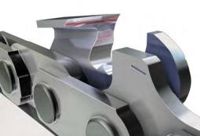

In order to prepare for sharpening your chainsaw chain, there a couple of things to consider, for instance the chipper tooth chain can be resharpened with a round file. Stihl carbide-tipped chains are called ‘Duro’ and they are particularly wear resistant and have extremely hard cutting edges - these have to be resharpened with a special diamond grinding wheel.

All other chainsaw chains can be resharpened relatively easily with the correct tools and the right technique.

When do I know if my chainsaw chain needs sharpening?

If one of the following conditions occurs, then it’s time to sharpen your chainsaw!

- The saw chatters and bounces during the cut (if this occurs, ensure you check the depth gauge settings).

- The chain does not pull itself into the cut and has to be forced to cut by applying pressure to the powerhead.

- There is smoke in the cut even though the chain lubrication is in order and the chain tension is correct.

- When bucking, fine sawdust is pulled from the cut instead of coarse, thick chips.

- The cut wanders in one direction. This is an indication of dull cutters on one side of the chain or irregular cutter lengths.

Preparing the chainsaw

Ensure you start by cleaning the chainsaw chain thoroughly. The chain should also be examined for signs of damage at the same time and if there’s any damaged or worn parts, replace them immediately.

If the wear marks have been reached, make sure you replace and install a new chain. Please Note: if you are unsure how to replace any chain or spare parts, please make sure you contact your local Stihl dealer.

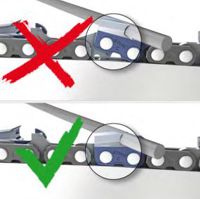

The chain must be tensioned tighter than normal when it’s resharpened. This prevents the cutters tipping, making it easier to maintain the correct angles. Once you have resharpened the chain, make sure you restore the chain tension to normal.

Find the shortest cutter and mark it is as the master cutter. All the other cutters in the chain have to be matched to the same length. Sharpen the master cutter first and then file all other cutters back to the same length.

Clamp the guide bar in a vice to suit the position of the master cutter.

Master cutter in right hand row

Clamp the guide bar with the nose facing to the left.

Master cutter in left hand row

Clamp the guide bar with the bar nose facing to the right.

Pull the master cutter into the filing position and the lock chain in position with the chain brake.

Disengage the chain brake to pull the saw chain along the bar and engage the brake again before filing the next cutters.

Sharpening Chainsaw Chain

Selecting the file

Firstly, select the diameter of the round file to suit the chain pitch.

Check the code digit for the chain pitch on the outboard side of the depth gauge, refer to the table below to obtain the chain pitch. Each chain pitch is assigned to a specific round file diameter (ensure you only use special saw chain sharpening files!).

| Code Digit on Depth Gauge Thread | Alternative Marking on Depth Gauge | Chain Pitch | Round File Diameter |

| 1 | 1/4 | 1/4" | 4.0 mm |

| 2 | 325 | .325" | 4.8 mm |

| 3 | 3/8 | 3/8" | 5.2 mm |

| 4 | 404 | .404" | 5.5 mm |

| 6 | P, PM | 3/8" Picco | 4.0 mm |

| 7 | 1/4" Picco | 3.2mm |

Holding the File

Hold the file handle firmly with one hand while guiding the file with the other hand across the cutter on the forward stroke.

Start with the master cutter, positioning the file so you’re able to apply pressure and file from the inside to the outside cutter.

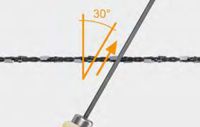

Always hold the file at a right angle (90°) to the guide bar.

The file only sharpens on the forward stroke - lift the file off the cutter on the backstroke!

Rotate the file a little at regular intervals while filing to help prevent one-sided wear.

Stihl saw chains are generally filed to an angle of 30° - parallel to the service mark for the filing angle.

Hold the file so that one quarter of its diameter projects above the top plate.

Stihl’s pro tip: Providing you observe these rules you should achieve the perfect sharpening results, the correct side plate and top plate angles will be obtained automatically and the best possible cutting performance guaranteed.

Before you start sharpening, mark one cutter with a felt tip pen and after a couple of strokes, check how much material has been removed.

If the surface appears uniform, your filing action is correct.

If there are still patches of colour in places, check you are using the correct file and ensure you’re not holding the file too high or low.

File the master cutter until the cutting edge is perfect.

Checking the result

If dark areas are visible on the cutting edge the cutter isn’t sharp enough!

It is properly sharpened when the cutting edge is unformingly bright.

Once correct, file all the cutters in that row to the same length and uniform. Then turn the chainsaw 180° and file all the cutters in the other row. Please remember all cutters must be the same length as the master cutter!

Stihl’s pro tip: Never continue working with the chain until it is completely dull. A few strokes of the file at regular intervals quickly restores full sharpness.

Count the number of file strokes and use the same number on each cutter to obtain cutters of identical length.

If you find that the cutters in one row are shorter than those in the other row, you have used more pressure while filing the row concerned. Correct the length of the cutters by performing one or two strokes of the file on the longer cutters.

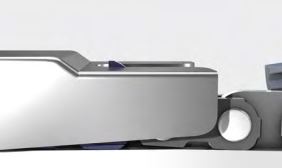

Lowering depth gauges:

When the cutter is sharpened the depth gauge setting will become smaller. Once the cutters are sharpened, check the depth gauge setting and adjust/ lower if necessary.

On a Stihl chain, the depth gauge setting can be increased by up to 0.2mm for cutting soft wood in mild weather conditions (excluding frost)! The filing gauge for the next chain pitch up may be used for this purpose.

| Chain Pitch | Depth Gauge Setting | ||

| Inch | (mm) | mm | Inch |

| 1/4 | 6.35 | 0.65 | 0.026 |

| 1/4 P | 6.35 | 0.45 | 0.018 |

| .325 | 8.25 | 0.65 | 0.026 |

| .325 | 8.25 | 0.65 | 0.026 |

| 3/8 | 9.32 | 0.65 | 0.026 |

| 3/8 P | 9.32 | 0.65 | 0.026 |

| .404 | 10.26 | 0.80 | 0.031 |

Simply place the filing gauge on the saw chain and if the depth gauge is higher than the filing gauge, it must be lowered.

As the filing gauge is not made of file hard material, it’s only suitable for use as a measuring tool. Ensure you remove the filing gauge from the chain before filing the depth of the gauge.

File the depth down of the gauge until its level with the filing gauge.

Stihl’s pro tip: Count the number of file strokes you need to lower the first depth gauge and file down all others with equal number of strokes so all the depth gauge settings should be the same. Remember to carry out a couple of random checks with the filing gauge.

On saw chains with humped drive links the hump is lowered along with the depth gauge.

File the top of the depth gauge parallel to the service mark - ensure you don’t lower the highest point of the depth gauge in the process.

Do not touch the freshly sharpened cutter with the flat file.

Please Note: the kickback tendency of the chainsaw is increased if the depth gauges are too low.