Stihl Chainsaw Guide Bar Maintenance

Stihl Guide Bar Maintenance

The area on a guide bar where most of the cutting is done is always affected more, this is usually the underside of the bar. Guide bars that do not have a nose sprocket (Duromatic bars), it is the nose area that’s highly stressed. Before mounting the guide bar and chain to the chainsaw:

- Clean the oil inlet holes and the bar groove (the groove cleaner on the filing gauge is suitable for this purpose).

- Check the groove depth

- Check the bar rails for burrs and deburr if necessary

- When bucking, fine sawdust is pulled from the cut instead of coarse, thick chips.

- Turn the bar over to ensure it wears evenly as possible on both sides

It’s best to use four saw chains with two chain sprockets and one guide bar in rotation - a 4-2-1 principle.

Groove depth

The bar groove becomes shallower as the rail wears. A medium depth must be maintained in order to ensure the drive link tangs do not scrape along the bottom of the groove. If this happens the drive link tangs wear very quickly and the running faces of the cutters and tie straps will no longer ride on the bar rails.

| Chain Pitch | Minimum Groove Depth |

| 1/4" P | 4mm |

| 1/4" | 4mm |

| 3/8" P | 5mm |

| .325" | 6mm |

| 3/8" | 6mm |

| .404" | 7mm |

Checking groove depth

Rollomatic guide bars with sprocket nose

Use the scale (groove cleaner) on a filing gauge to check the groove depth on the top and bottom of the guide bar.

Duromatic guide bars without sprocket nose

Use the scale (groove cleaner) on a filing gauge to check the groove depth over its entire length.

Make sure you replace the guide bar if the measured depth is less than specified!

Deburring bar rails

A burr will form on the outer edges of the bar rails as they wear

This burr can be removed with a flat file or the Stihl guide bar dressing tool.

If the left and right bar rails have been worn unevenly due to an incorrectly sharpened chain. This can be levelled with the Stihl guide bar dressing tool providing the difference is not too great

It’s important the required minimum groove depth is maintained after the rails have been levelled.

If the guide bar has more serious damage, please contact your local Stihl servicing dealer for assistance.

Wear on a guide bar

A saw chain that’s been too loosely tensioned over a prolonged period of time, it may have a negative effect on the condition of the guide bar.

If these effects are identified within good time, measures can be taken to counteract the high rate of wear. For this reason the guide bar should be checked at regular intervals for signs of abnormal wear.

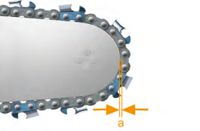

Checking nose sprocket of Rollomatic guide bar

There must be a clearance (a) between the chain and bar nose. If there’s no clearance, for example, the chain locates against the bar nose, it indicates the nose sprocket teeth are worn or the nose sprocket bearing is damaged.

Worn guide bar rails

There must be a clearance (a) between the chain and bar nose. If there’s no clearance, for example, the chain locates against the bar nose, it indicates the nose sprocket teeth are worn or the nose sprocket bearing is damaged.

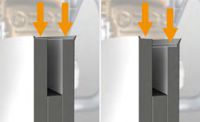

Left: Evenly worn bar rails, minimum depth has been reached, normal wear - replace the whole cutting attachment.

Right: Unevenly worn bar rails.

| Error | Unevenly worn bar rails due to incorrectly sharpened chain |

| Effects | Chain tips to one side and doesn't cut straight |

| Remedy | Level the bar rails and sharpen the chain correctly. If the minimum groove depth cannot be maintained, replace the cutting attachment. |

Worn guide bar rails

Bar rails battered at top entry area and at bottom behind nose; underside of bar ripped.

| Error | Chain tensioned too loosely for extended period |

| Effects | Chain runs roughly. Using a guide bar in this state will cause it and the chain to wear very quickly. |

| Remedy | Level the bar rails. If damage is to advanced, install a new cutting attachment (chain sprocket, guide bar, chain). If only one of these parts is replaced, it will be quickly worn again by the other defective parts. |

Pinched or splayed guide bar rails

| Error | Force has been used, for example, guide bar pinched in cut |

| Effects | Chain wobbles or is jammed |

| Remedy | Your Stihl servicing dealer will access whether the guide bar can be repaired or has been replaced. |

Guide Bar rails chipped

| Error | Burr on guide bar not removed soon enough |

| Effects | Chain runs roughly and wears rapidly |

| Remedy | - Level bar rails if minimum bar groove depth can be maintained - If bar wear is too advanced, have rails levelled by a Stihl servicing dealer - Replace the guide bar if necessary - Always remove burns in good time |

Stihl recommends contacting your Stihl servicing dealer if one of the conditions listed occurs is a more serious form and are not able to be rectified easily.