Related Posts

3 Item(s)

Buy Stihl Chainsaw Spare Parts and Accessories Here »

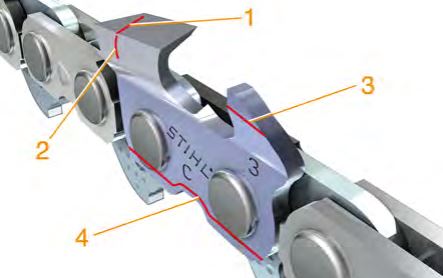

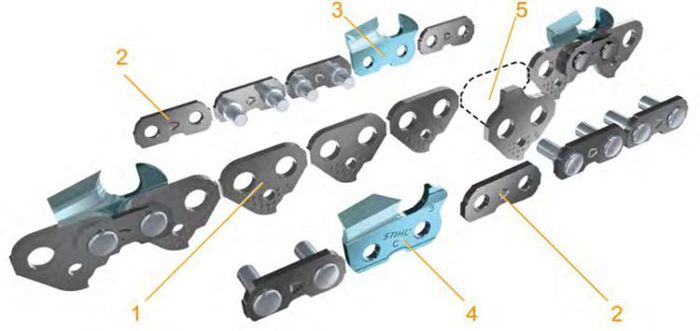

Stihl chainsaw chains are three-link chains that are always assembled in the same basic pattern. The shape of the cutters may differ in their shape, as well as the dimensions of the individual links.

The low kickback chains have a humped drive link, these are identified by the digit 3 in their designation, for example: 36 RS3.

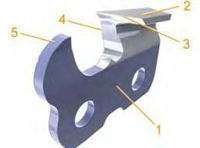

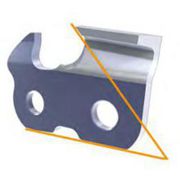

To get the optimum cutting performance from your chainsaw, it’s critical the side and top plate of the cutting edges are at a given angle in relation to one another. The angle is obtained automatically if the exact sharpening angles are observed.

The cutters work on the chipper tooth principle, which removes chips from the wood. During this process, the top plate cutting edge lifts the chip off the bottom of the cut, while the side plate cutting edge separates the chip from the wall of the cut.

The depth gauge setting determines the height at which the cutter enters the wood and the thickness of the chip that’s removed.

The difference in height between the top of the depth gauge and the leading edge of the top plate is known as the depth gauge setting.

To ensure the chain runs evenly and smoothly, you need to ensure all cutters are the same length and sharpened to the specific angle.

The majority of chainsaw chains show service and wear markings to simplify resharpening and enable the rate of wear. To ensure this is monitored, follow these steps: