Related Products

Related Posts

2 Item(s)

Lifting chains are a critical component of many heavy-duty lifting and rigging operations. These chains are designed to handle heavy loads and ensure the safe and efficient handling of materials. This guide will include lifting chain components, how to select the right one, certification, and the all important dos and don'ts.

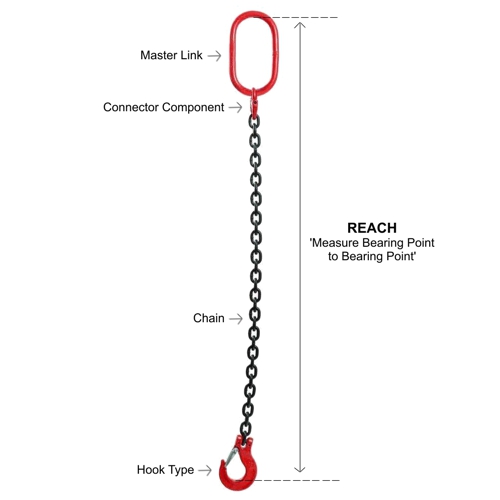

The various components of lifting chains play a crucial role in their safety and reliability. These components include the grade of steel, the diameter of chain, chain legs, component connectors and hooks.

Grade of Steel:

The two most commonly used grades in lifting chains are Grade 80 and Grade 100 steel. Grade 80 steel is appropriate for most heavy-duty applications and is more widely used, while Grade 100 is stronger and more durable but also more expensive.

Chain Diameter:

The diameter of the chain affects its strength. The larger the diameter, the stronger the chain. Common diameters used in lifting chains include 3/8", 1/2", 5/8", and 3/4".

Chain Legs:

Chain legs are the individual links that make up the chain assembly. The length of the chain legs determines the overall length of the assembly.

Component Connectors:

Component connectors join the chain legs to form the complete chain assembly. They come in different shapes and sizes, such as master links, connecting links, and sling hooks.

Hooks:

Hooks are used to attach the chain to the load being lifted. Different hooks include eye hooks, clevis hooks, and slip hooks, and the right one to use depends on the type of load being lifted.

Shop our Wide Range of Hooks and Connectors Here »

Choosing the right lifting chain assembly is important to ensure the lift is both safe and efficient. Consider the following factors when selecting a lifting chain:

Load Capacity:

The most crucial factor is the load capacity of the lifting chain, which is determined by its strength, diameter, and number of chain legs. Make sure the chosen lifting chain can support the weight of the load being lifted.

Length:

The length of the lifting chain will determine the height of the lift. Make sure the length is sufficient for the lift you will perform.

Hooks:

The type of hooks used will determine how the chain is attached to the load. Ensure the chosen hooks are suitable for the type of load being lifted.

Environment:

The environment in which the lifting chain will be used can also affect its performance. It's important to consider factors that could affect it such as temperature, humidity, and exposure to corrosive substances when selecting the lifting chain.

Once the grade of steel, chain diameter and number of chain legs in the chain assembly has been decided, this will determine the Working Load Limit of the chain assembly.

To ensure safe and efficient use of lifting chains, it's important to follow certain dos and don'ts.

Do:

Don't: