Introduction

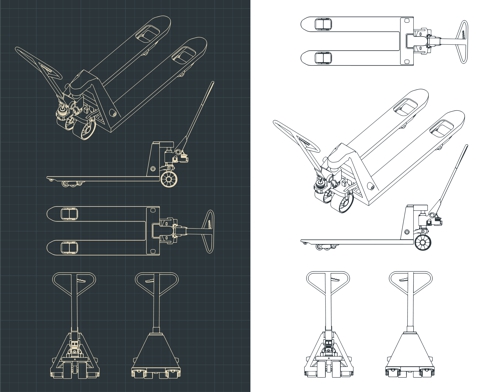

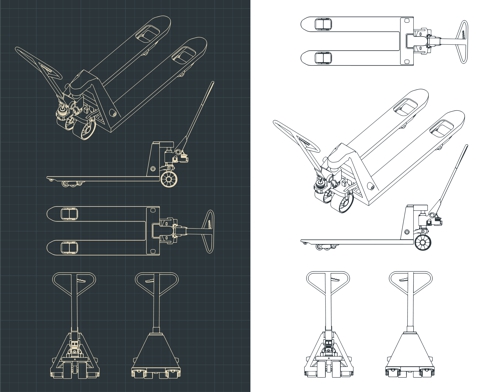

A pallet truck, commonly referred to as a pump truck or pallet jack, is a specialised wheeled device created for the purpose of elevating and moving pallets. Its uniquely shaped forks smoothly fit beneath the pallet, allowing the user to utilise the pump handle to effortlessly raise or lower the load. These are available as manual or electrical.

Pallet trucks are integral tools found in warehouses, distribution centres, and manufacturing facilities, serving a vital function in streamlining material handling within the logistics and supply chain sector.

The hydraulic system of a pallet truck enables effortless movement by either pushing or pulling with equal force. While the decision to push or pull is often a matter of personal preference and circumstances, pushing is generally considered more safe. By utilising your body weight, pushing allows for better control and directs the pallet truck forward with ease, rather than struggling to drag it behind you.

How to Operate a Pallet Truck?

To operate a pallet truck effectively, follow these precise guidelines:

First things first, safety is priority and operating a pallet truck could lead to injury. For the safety of both the user and other employees, ensure you push, pull and lift with your legs for balance rather than with your back for power. This is the most effective method and will help to prevent pulling a muscle or damaging your back.

- To begin, smoothly slide the forks underneath the open spaces of the pallet you intend to move, ensuring the handle remains upright.

- Before initiating movement, securely fasten both the pallet and its contents to the pallet truck. If there are concerns about stability during transportation, reinforce the item by securely attaching it to the pallet.

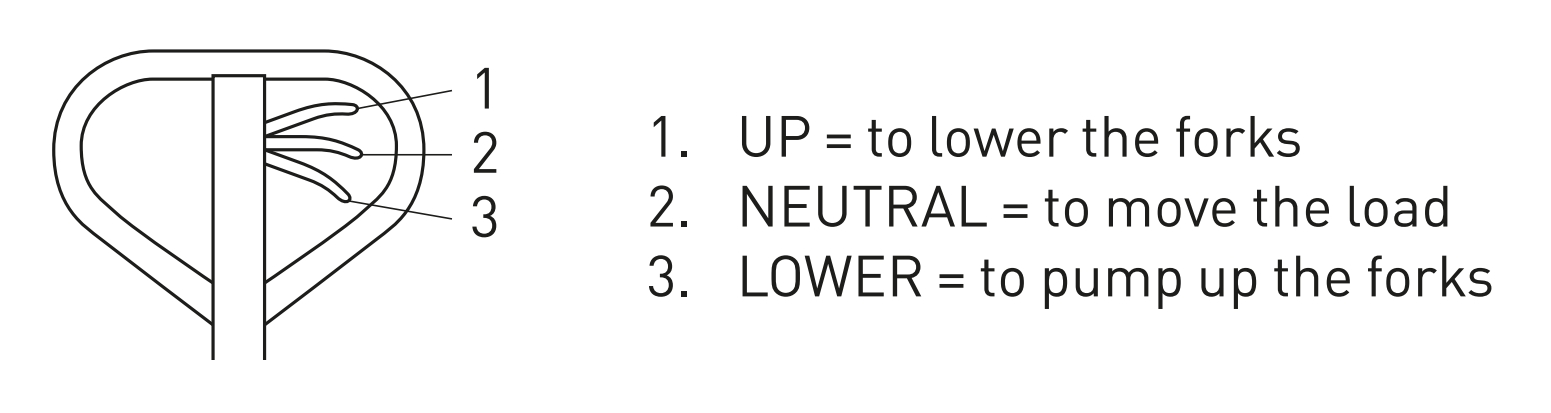

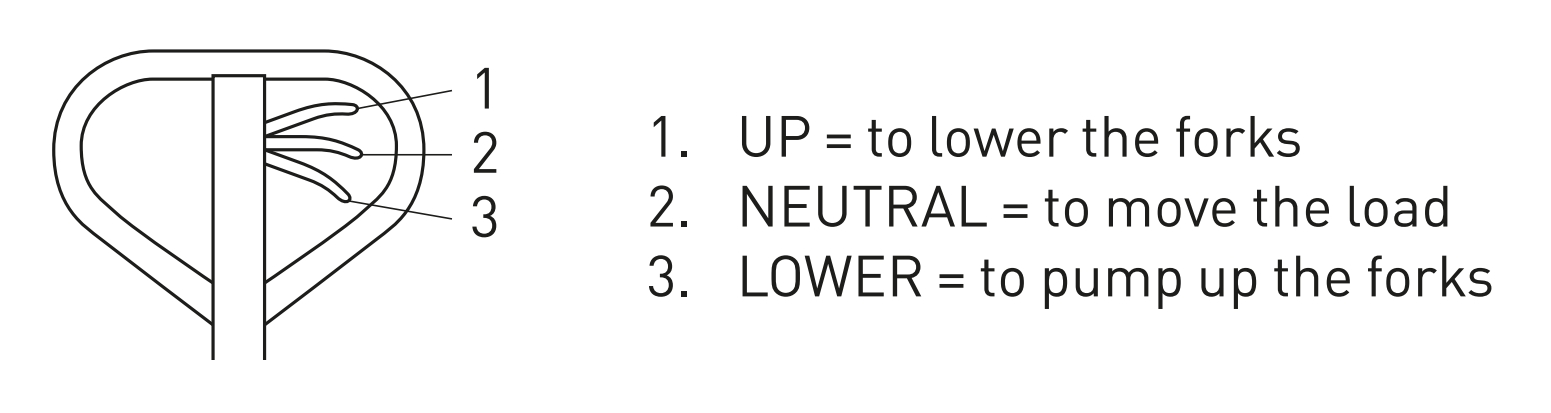

- Move the control lever to the down position and pump the handle to gradually raise the forks until a noticeable gap is created between the pallet and the floor surface.

- When ready to move, place the control lever back to the neutral position. Then apply downward pressure on the handle while upright to propel the pallet truck in the desired direction. For better grip and control, coordinate your hand movements with the direction of travel, switching between the left and right hand for leftward or rightward manoeuvres.

- Maintain a vigilant and alert stance, continuously scanning for individuals or obstacles that may obstruct the intended path. By maintaining a safe and controlled pace, unforeseen accidents can be effectively prevented.

- Plan the final destination for the pallet in advance. Upon reaching the designated location, pull the control lever up to gently lower the forks until the pallet securely rests on the ground. Carefully disengage the forks from beneath the pallet at this point.

How to Maintain a Pallet Truck:

Ensuring the longevity and safety of pallet trucks hinges on regular maintenance. This includes checking and lubricating moving parts, inspecting the hydraulic system, and replacing worn-out components.

-

Operator Training:

Ensure that operators are properly trained in the correct use of the pallet truck. This includes understanding load capacities, proper handling techniques, and safety precautions.

-

Regular Inspections:

Conduct daily visual inspections before use. Look for any signs of damage, such as bent forks, leaks, or worn-out wheels. Check for loose bolts, nuts, or other fasteners. Tighten them as needed.

-

Lubrication:

Regularly lubricate all moving parts, including joints, pivot points, and wheels. This helps reduce friction and wear. Use a manufacturer recommended lubricant.

-

Fork Inspection:

Ensure that the forks are straight, not bent or twisted. Damaged forks can compromise load stability and safety. Check for any cracks or signs of stress on the forks.

-

Wheels and Tyre:

Inspect wheels for wear, flat spots, or damage. Replace any damaged or excessively worn wheels. Keep tyres properly inflated, especially in the case of pneumatic tyres.

-

Hydraulic System:

Check the hydraulic pump and cylinder for leaks. Address any hydraulic fluid leaks you find. Test the lift and lower functions to ensure they are working smoothly.

-

Load Capacity:

Adhere to the pallet truck's load capacity. Avoid exceeding the recommended weight limits to prevent damage and ensure safe operation.

-

Battery Maintenance (for Electric Pallet Trucks)

If your pallet truck is electric, monitor the battery regularly. Charge it according to the manufacturer's recommendations. Inspect battery cables and connectors for signs of wear or corrosion.

-

Cleanliness:

Keep the pallet truck clean from debris, dirt, and other contaminants. Regular cleaning helps prevent damage and ensures smooth operation.

-

Follow Manufacturer's Guidelines:

Always follow the manufacturer's guidelines and recommendations for maintenance and service intervals. These guidelines are designed to keep the pallet truck in optimal condition.

Shop our Wide Range of Pallet Trucks Here »

Shop our Wide Range of Pallet Trucks Spares & Accessories Here »

![]() 3000kg Double Wheel Pallet Truck£396.36 £330.30

3000kg Double Wheel Pallet Truck£396.36 £330.30![]() 2500kg Double Wheel Pallet Truck - Ideal for Warehouse£384.36 £320.30

2500kg Double Wheel Pallet Truck - Ideal for Warehouse£384.36 £320.30![]() High Lift Pallet Truck 1000kg 1170 x 540mm - Sealey No. PT1170H£1,124.40 £937.00

High Lift Pallet Truck 1000kg 1170 x 540mm - Sealey No. PT1170H£1,124.40 £937.00![]() Pallet Truck with Scales 2000kg 1150 x 555mm - Sealey No. PT1150SC£1,684.75 £1,403.96

Pallet Truck with Scales 2000kg 1150 x 555mm - Sealey No. PT1150SC£1,684.75 £1,403.96![]() Pallet Truck 2200kg 1150 x 525mm Sealey Part No. PT2200£683.94 £569.95

Pallet Truck 2200kg 1150 x 525mm Sealey Part No. PT2200£683.94 £569.95